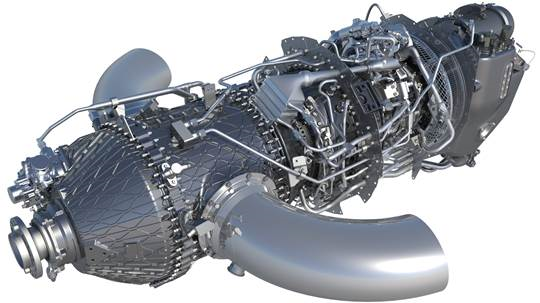

GE’s Catalyst™ – a new turboprop engine

GE’s Catalyst™ is a new GE turboprop engine for the Business & General Aviation segment in the 850‑1,650 SHP range. This engine features a new aero design high pressure ratio compressor and a cooled high pressure turbine that enable lower fuel burn and higher cruise power compared to competitors. Use of an additive technology allows to replace around 800 conventionally manufactured components with just a few printed parts. Integrated FADEPC engine and propeller control system offers cockpit simplification and unmatched pilot experience.

This development program is led by an international team of over 400 engineers from, among others, Poland, Czech Republic, Germany, Italy and USA. Over 200 EDC engineers design major GE Catalyst modules, including Compressor, High Pressure Turbine, Low Pressure Turbine, Bearings and Sumps. Advanced hot section cooling technology was developed by EDC to meet GE’s Catalyst™ high power and performance requirements. Our engineers also design a number of innovative additive components that help reduce weight and simplify the engine architecture. Our design responsibility includes all development phases from the conceptual phase thru the engine certification, as well as key disciplines including systems integration, mechanical design, thermal, secondary flows, lubrication and pressurization systems.

EDC Digital team supports the Catalyst program with latest data analytics applied in such fields as test data analysis, cost and program KPIs visualization.

Media Publications

- NEW! Euro Engine (in Polish and in English)

- NEW! From Berlin’s to Wichita skies (in Polish)

- NEW! Interview with Catalyst Systems Leader in Unmanned Systems Technology

- NEW! The Catalyst™ engine completed its first single-engine flight

- NEW! Beechcraft Denali Aces First Flight (movie)

- The Turbocharger (interview with EDC engineer about GE Catalyst)

- Catalyst for change (article about how the engine propels an industry forward)

- Advanced Turboprop engine compressor test (movie)

- Advanced Turboprop first engine run (movie)

- Advanced Turboprop first engine run (press release)

- GE Catalyst overview (GE Aviation website)

- GE Catalyst – a new name for Advanced Turboprop (press release)

- Advanced Turboprop engine introduction (movie)

- Customer view on Advanced Turboprop engine (movie)

- Additive for Advanced Turboprop engine (movie)